Nanocasting custom-shaped metal nanoparticles in DNA molds

October 13, 2014

Silver cuboid particle chart alongside square watermelon. The concept of casting nanoparticles inside DNA molds resembles the Japanese method of growing watermelons inside cube-shaped glass boxes. (Credit: Harvard’s Wyss Institute/Peng Yin)

Extending 3D printing of metals to the nanoscale, researchers at the Wyss Institute for Biologically Inspired Engineering at Harvard University have developed a new method of forming 3D metal nanoparticles in prescribed shapes and dimensions using DNA as a construction mold.

The ability to mold inorganic nanoparticles out of materials such as gold and silver in precisely designed 3D shapes is a significant breakthrough that has the potential to advance laser technology, microscopy, solar cells, electronics, environmental testing, disease detection, and more, the researchers say.

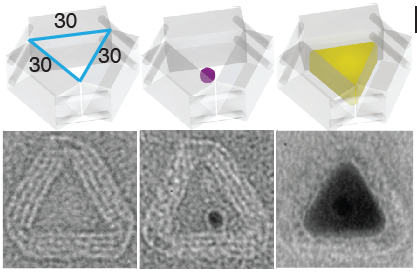

Polygonal-shaped particle formation. By creating molds from stiff DNA, researchers were able to cast gold “seeds” into complex metal nanoparticles. Top: schematics how the 3D polygonal particle was formed by designing a DNA mold, planting a gold seed, then chemically forcing the seed to expand until complete formation. Bottom; corresponding TEM images. (Credit: Harvard’s Wyss Institute)

“We built tiny foundries made of stiff DNA to fabricate metal nanoparticles in exact three-dimensional shapes that we digitally planned and designed,” said Peng Yin, senior author of the paper, Wyss Core Faculty member and Assistant Professor of Systems Biology at Harvard Medical School.

The Wyss team’s findings, ,in collaboration with MIT’s Laboratory for Computational Biology and Biophysics, were published Oct. 9 in Science.

“The paper’s findings describe a significant advance in DNA nanotechnology as well as in inorganic nanoparticle synthesis,” Yin said. “For the very first time, a general strategy to manufacture inorganic nanoparticles with user-specified 3D shapes has been achieved to produce particles as small as 25 nanometers or less, with remarkable precision (less than 5 nanometers).”

DNA nanocasting

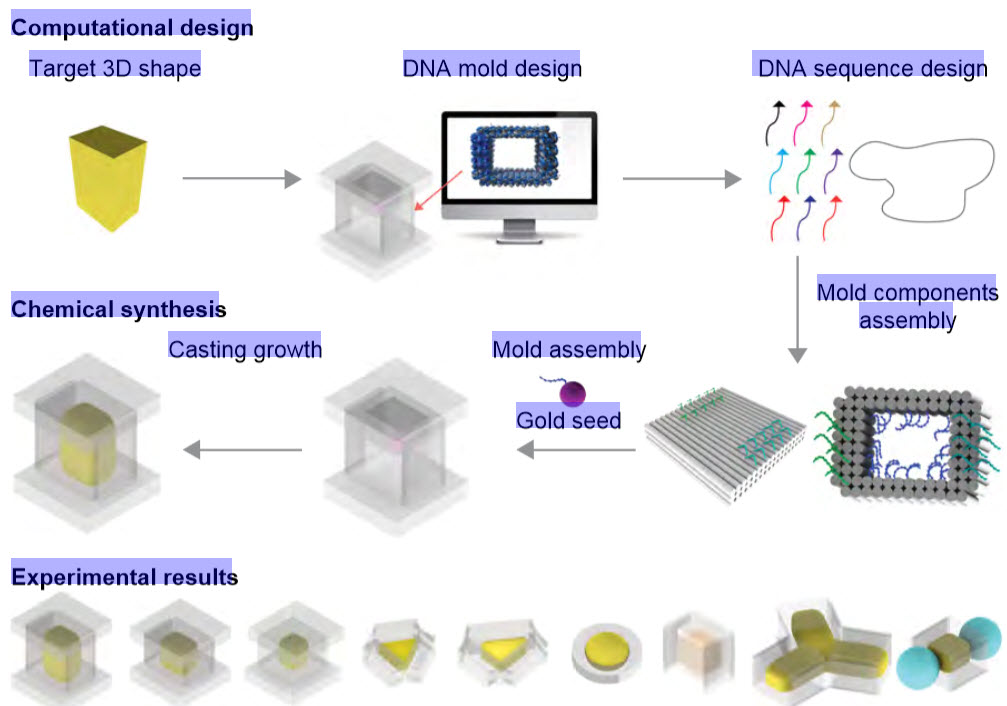

The 3D inorganic nanoparticles are first conceived and meticulously planned using computer design software. Using the software, the researchers design 3D “frameworks” of the desired size and shape, built from linear DNA sequences, which attract and bind to one another in a predictable manner.

“Over the years, scientists have been very successful at making complex 3D shapes from DNA using diverse strategies,” said Wei Sun, a postdoctoral scholar in the Wyss’ Molecular Systems Lab and the lead author of the paper. For example, in 2012, the Wyss team revealed how computer-aided design could be used to construct hundreds of different self–assembling one–, two–, and three–dimensional DNA nanoshapes with perfect accuracy.

This ability to design arbitrary nanostructures using DNA manipulation inspired the Wyss team to envision using these DNA structures as practical foundries or “molds” for inorganic substances.

From a gold seed …

Casting metal particles with prescribed 3D shapes using programmable DNA nanostructure molds. Top: computational shape-by-design framework to encode the user-specified 3D shape of an inorganic particle in the linear sequences of DNA. Bottom: assembly of the mold and casting growth of the metal particle. (Credit: Harvard’s Wyss Institute0/Peng Yin)

“The challenge was to translate this kind of 3D geometrical control into the ability to cast structures in other diverse and functionally–relevant materials, such as gold and silver,” Sun said.

Just as any expanding material can be shaped inside a mold to take on a defined 3D form, the Wyss team set out to grow inorganic particles within the confined hollow spaces of stiff DNA nanostructures.

The concept can be likened to the Japanese method of growing watermelons in glass cubes. By nurturing watermelon seeds to maturity inside cube–shaped glass boxes, Japanese farmers create cube-shaped mature melons that allow for densely–packed shipping and storage of the fruit.

The Wyss researchers similarly planted a miniscule gold “seed” inside the hollow cavity of their carefully designed cube-shaped DNA mold and then stimulated it to grow. Using an activating chemical solution, the gold seed grew and expanded to fill all existing space within the DNA framework, resulting in a cuboid nanoparticle with the same dimensions as its mold, with the length, width and height of the particle able to be controlled independently.

Next, researchers fabricated varied 3D polygonal shapes, spheres, and more ambitious structures, such as a 3D Y-shaped nanoparticle and another structure comprising a cuboid shape sandwiched between two spheres, proving that structurally diverse nanoparticles could be shaped using complex DNA mold designs.

Despite their small size, stiff DNA molds are proportionally quite robust and strong, able to withstand the pressures of expanding inorganic materials. Although the team selected gold seedlings to cast their nanoparticles, there is a wide range of inorganic nanoparticles that can be forcibly shaped through this process of DNA nanocasting.

Detecting early-stage cancers and genetic diseases

A very useful property is that once cast, these nanoparticles can retain the framework of the DNA mold as an outer coating, enabling additional surface modification with impressive nanoscale precision. These coatings can also help scientists develop highly sensitive, multiplex methods of detecting early–stage cancers and genetic diseases by combining the chemical specificity of the DNA with the signal readout of the metal.

The DNA framework coating can be quickly and easily broken down and removed to produce pure metal wires and connectors for use in computational and other electronic devices.

“The properties of DNA that allow it to self-assemble and encode the building blocks of life have been harnessed, re-purposed and re-imagined for the nanomanufacturing of inorganic materials,” said Don Ingber, Wyss Institute founding director.

“This capability should open up entirely new strategies for fields ranging from computer miniaturization to energy and pathogen detection.”

Abstract of Casting inorganic structures with DNA molds

We report a general strategy for designing and synthesizing inorganic nanostructures with arbitrarily prescribed three-dimensional shapes. Computationally designed DNA strands self-assemble into a stiff “nano-mold” that contains a user-specified three-dimensional cavity and encloses a nucleating gold “seed”. Under mild conditions, this seed grows into a larger cast structure that fills and thus replicates the cavity. We synthesized a variety of nanoparticles with three nanometer resolution: three distinct silver cuboids with three independently tunable dimensions, silver and gold nanoparticles with diverse cross sections, and composite structures with homo-/heterogeneous components. The designer equilateral silver triangular and spherical nanoparticles exhibited plasmonic properties consistent with electromagnetism-based simulations. Our framework is generalizable to more complex geometries and diverse inorganic materials, offering a range of applications in biosensing, photonics, and nanoelectronics.